We stock 146 AS-Motor products

X-ACT TRACK Steering assistant

£11,900.00 INC VAT

- Automatic steering system for AS-Motor RC mowers using centimetre-accurate RTK guidance.

- Reduces operator fatigue on long runs by handling straight-line mowing and repeatable patterns.

- Improves area output with clean overlaps and no missed strips.

- Ideal for solar farms, reservoirs, banks and larger open areas.

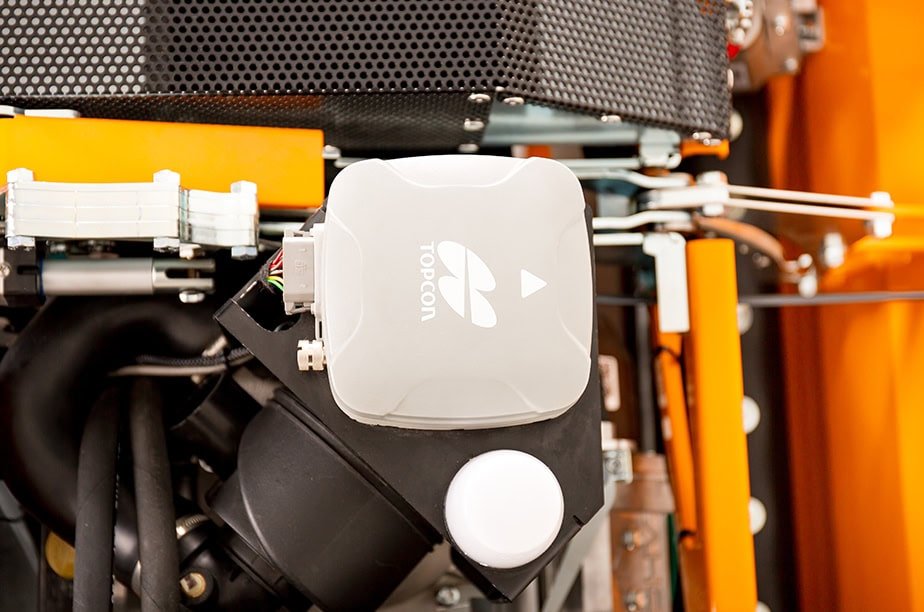

- Proven TOPCON technology adapted for remote-controlled slope mowers.

- Clear touchscreen terminal with mirrored control via mobile device.

- Supports semi-autonomous mowing patterns, including A-B lines and bypassed-area modes.

- Built for professional use with reliable components and dealer-backed support.

X-ACT Track steering assistant is AS-Motor’s automatic steering system for their remote-controlled mowers, designed to keep the machine on line while you focus on the job instead of micromanaging every pass. Using RTK-corrected GPS, it holds clean, repeatable mowing lines on banks, verges and open ground so you’re not constantly correcting the joysticks or guessing the overlap.

On large or repetitive sites, X-ACT Track turns an RC mower into a much more efficient tool: you set the boundaries and pattern, and the steering assistant takes care of the straight work while you monitor and step in where needed. It’s particularly useful on solar farms, reservoirs and long embankments where consistency, output and operator concentration all matter. Paired with an Ovis, Tahr or similar machine supplied by Suffolk Mowers, it gives you a smarter way to cover serious ground without wearing the operator out.

From automation to autonomy

Fully autonomous mowing is coming, but we’re not there yet. X-ACT Track sits at an early stage of automation, where the steering assistant keeps the mower on its line and can turn within set boundaries, while the operator still defines the working area and keeps everything under supervision. In automation terms that’s level 1–2 on a 6-step scale, with level 6 representing full autonomy.

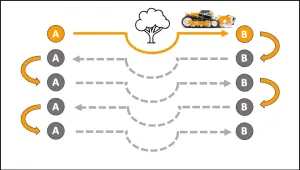

A-B line repetition

Points A and B are recorded once. X-ACT Track then divides the area into parallel lines and mows them one after another. Turning is carried out manually, and you can choose which line to drive next. The mowing pattern can be adapted to the shape of the area.

A-B curve repetition

The system records the travel path between points A and B as a curve. This curved route is then repeated in parallel across the whole area. Turning remains manual, and you can still decide which line to follow next. It’s useful where the boundary or mowing line isn’t straight.

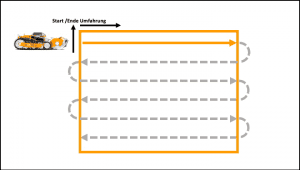

Automatic mowing of a bypassed area

First, you drive around the boundary and complete the initial line. After that, X-ACT Track automatically mows the enclosed area. The system takes care of the turning manoeuvre at the boundary, while you monitor the process and step in if needed.

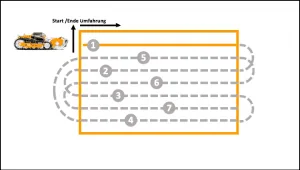

Automatic mowing according to pattern

Several automatic mowing programmes are available for bypassed areas. X-ACT Track uses larger turning radii to protect the ground, and the turning movements are handled automatically. The operator continues to supervise the process and can intervene at any time.

How X-ACT Track Improves Real-World Mowing

X-ACT Track takes the hardest part of remote-controlled mowing—the constant steering corrections—and hands it off to a guidance system designed for agricultural work. When you’re managing large areas, long passes or open banks, this removes the need to watch every centimetre of overlap. The result is steadier lines, fewer missed strips and a clear gain in area output, especially over long shifts.

The steering assistant uses RTK-corrected GPS to hold its path with impressive accuracy. You set the area boundaries, choose the mowing pattern and let the system handle the straight running. It’s a major advantage on solar farms, reservoirs, verges and other large or predictable sites where concentration usually fades after an hour. Instead of constantly nudging the joysticks, the operator can focus on monitoring terrain changes, safety and the sections that actually require manual input.

Where X-ACT Track Fits in the AS Range

The system pairs naturally with AS-Motor’s remote-controlled crawlers such as the Ovis, Ovis EVO and Tahr RC. These machines already excel on slopes and awkward ground; X-ACT Track simply makes them more productive on the long, repetitive runs that normally slow operators down. It won’t replace the operator, but it will take away the workload that humans tend to get worse at as the day goes on.

Practical Gains for Professional Users

- Cleaner, repeatable mowing lines with no drifting overlap.

- Reduced operator fatigue—ideal for long shifts or large contracts.

- More consistent results for councils and contractors working to presentation standards.

- Better fuel use and time savings across large sites.

- Compatible with several mowing patterns for different site layouts.

Designed for Field Use, Not Theory

Despite the advanced guidance, X-ACT Track is intentionally simple. The touchscreen terminal is clear, the system is built around proven TOPCON components and the mower still behaves like a normal RC machine when operated manually. Turning can be handled by the operator or automatically, depending on the chosen pattern. The setup is practical, serviceable and made for real-world conditions rather than lab testing.

How Suffolk Mowers Supports X-ACT Track Installations

Suffolk Mowers doesn’t just supply the X-ACT Track steering assistant as a box of parts and wish you luck. We work with you to match the system to the right AS-Motor machine, discuss how you plan to use it, and make sure the installation and setup are done correctly. That includes basic pattern setup, A–B line use and how to get the best from RTK guidance on your sites.

Once the system is in service, we remain your first point of contact for support. We can liaise with AS-Motor and TOPCON where needed, help with updates, troubleshooting and hardware checks, and supply replacement components if anything is damaged in the field. The goal is simple: keep your mower and guidance working together reliably, so your operators can cover more ground with less effort and less downtime.

Technical Specifications

| Guidance type | RTK-corrected GPS/GNSS automatic steering assistant |

| Accuracy | Centimetre-level with RTK correction data |

| Automation level | Level 1–2 (semi-autonomous steering with operator supervision) |

| Mowing patterns | A-B line, A-B curve, bypassed-area automatic, guided pattern modes |

| Control interface | LED touchscreen terminal with mirrored mobile operation |

| Core components | GPS/GNSS receiver, onboard processor, GSM module with SIM |

| Compatibility | AS-Motor remote-controlled mowers (Ovis RC, Ovis EVO RC, Tahr RC) |

| Steering functions | Automatic line-holding and turning (depending on mode) |

| Operator input required | Boundary setup, pattern selection, safety monitoring |

| Connectivity | GSM network link for RTK correction |

| Manufacturer partnership | TOPCON — global provider of surveying & agricultural guidance systems |

Frequently Asked Questions About X-ACT Track

Do I still need to operate the mower when X-ACT Track is running?

How accurate is the guidance?

Does it work on slopes?

Is it difficult to set up?

What happens if the GNSS signal drops?

Will it work on small, awkward sites?

Does it turn the mower automatically?

Is the system hard to service?

Part Numbers and EAN Codes

The X-ACT TRACK Steering assistant has an official Part Number (MPN) and EAN code. Details:

| Brand | MPN | EAN | Delivery Time |

|---|---|---|---|

| AS-Motor | G90500201 | 1–3 Days |

| Power Type |

|---|

No accessories found. If you need something specific, email us.

Q & A

X-ACT TRACK Steering assistant

X-ACT TRACK Steering assistant

Related products

Delivery Time: 1–3 Days

£35.80 INC VAT

WAS £38.90

Delivery Time: 1–3 Days

£77.28 INC VAT

WAS £84.00

Delivery Time: 1–3 Days

£6.07 INC VAT

WAS £6.60

Delivery Time: 1–3 Days

£44.16 INC VAT

WAS £48.00

Stihl

Stihl