Eliet Shredder Parts, Blades & Screens

Eliet shredder parts are central to throughput, chip quality and how well the machine handles different types of waste. Sharp, correctly matched blade kits keep shredding efficient, while the right screen or grating helps control output and reduce blockages, especially with wetter material.

Replacing worn parts at the right time restores performance and helps the shredder run smoothly without forcing feed or overworking the machine.

£642.00 INC VAT

£567.00 INC VAT

£471.00 INC VAT

£414.00 INC VAT

£339.00 INC VAT

£249.00 INC VAT

£213.00 INC VAT

£147.00 INC VAT

£111.00 INC VAT

£37.67 INC VAT

Keeping Eliet Shredders Working Efficiently

Eliet shredders rely on sharp blades and correct screen choice to process material cleanly and consistently. As blades wear, shredding slows, vibration increases and more effort is needed to feed material. Screens that are no longer suited to the waste being processed can also contribute to blockages.

Replacing blade kits and adjusting screens brings the shredder back to its intended working behaviour. It improves throughput, reduces strain on the machine and makes day-to-day use noticeably easier.

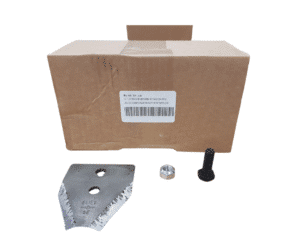

Blade Kits in Real Use

Eliet shredders are designed to run with complete, matched blade sets. These maintain rotor balance and cutting geometry, which is why replacing full kits is recommended rather than individual blades.

Screens & Gratings

Screens and gratings control how material exits the shredder. Multi-purpose screens suit mixed garden waste, while wet waste screens are used where damp, leafy or stringy material would otherwise clog the machine.

Fitment, Material Choice & Machine Compatibility

Eliet shredder parts are model-specific, and correct fitment matters. Blade count, blade type and screen design all vary between Maestro, Minor, Major and Prof-series machines. Matching the correct parts keeps the rotor balanced and the shredder working smoothly.

Material choice also plays a role. Switching between dry, woody waste and wetter green material often calls for a different screen or grating. Adjusting the setup to suit conditions helps avoid blockages and unnecessary wear.

Support, Advice & Ongoing Use

Shredder parts are working components, not cosmetic spares. Choosing the right blade kit and screen combination has a direct impact on throughput, reliability and running costs.

Suffolk Mowers supports Eliet shredder owners with accurate parts matching and practical advice based on real use, helping keep machines productive throughout the season.

Stihl

Stihl